- CO280 and CREW Carbon (CREW) will remove a total of 296,378 tons of CO₂ on behalf of Frontier members by 2030.

- Industrial retrofits alone could remove over 1 billion tons of CO₂ per year at low cost.

Frontier has facilitated $80 million in offtake agreements with two companies integrating carbon removal technology into existing industrial processes. CO280 develops Biomass Carbon Removal and Storage (BiCRS) projects at pulp and paper facilities, while CREW removes CO₂ from the wastewater treatment process. These integrations marry technological innovation with the ability to build and effectively run large infrastructure projects – a combination that could deliver billions of low-cost tons of CO₂ removal in the near future. Frontier buyers will pay CO280 $48.0 million to remove 224,500 tons of CO₂ between 2028 and 2030, and CREW $32.1 million to remove 71,878 tons of CO₂ between 2025 and 2030.

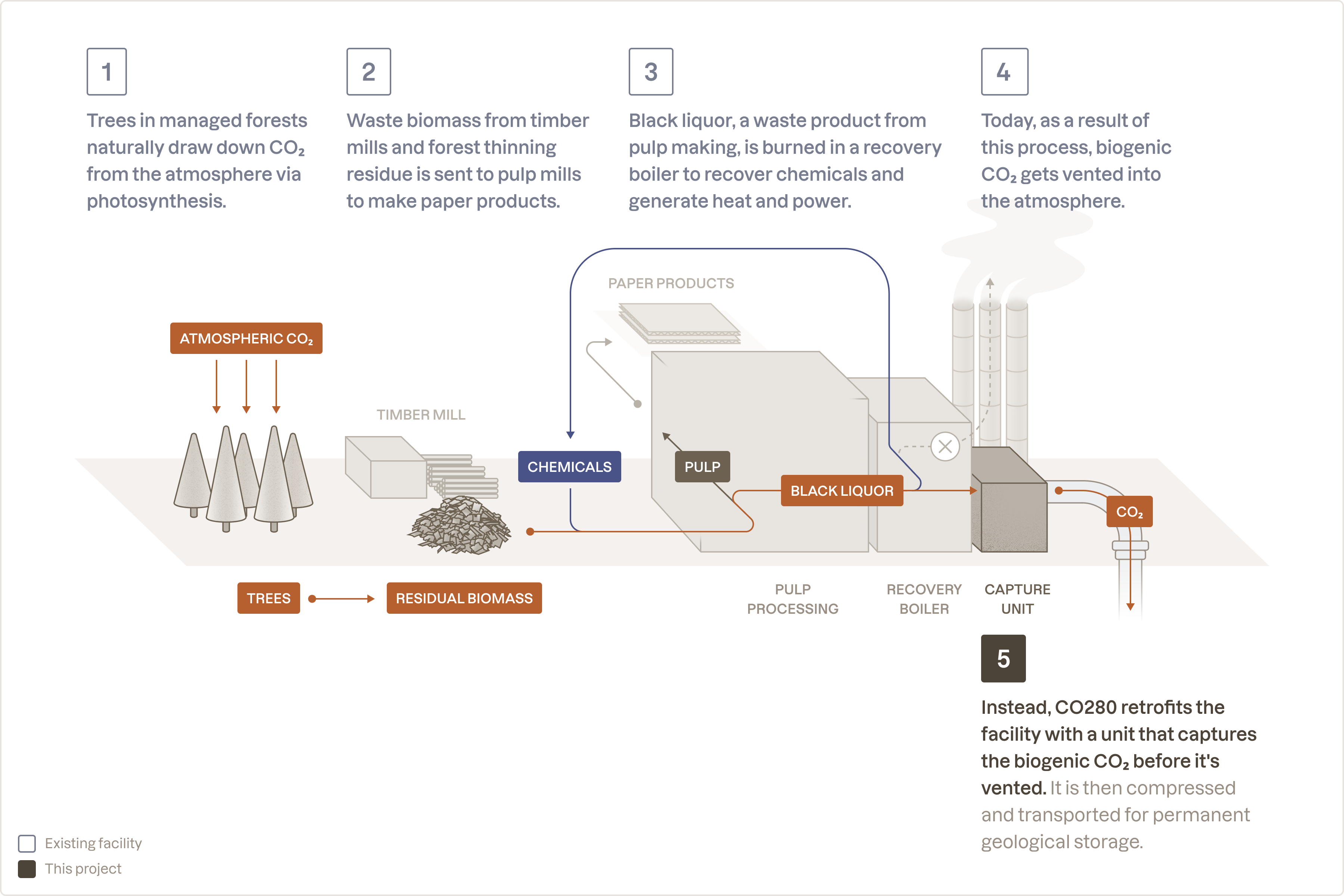

CO280 partners with pulp and paper companies to remove CO₂ produced in the manufacturing of pulp, which is used to make containerboard, cardboard packaging, tissue and other paper products. A pulp and paper mill first processes incoming biomass into a pulp, using steam, a mixture of chemicals, and pressure. The leftover waste from the initial processing, known as black liquor, is fired in a recovery boiler to recycle chemicals back into the mill and provide heat and power for the facility. CO280’s projects capture biogenic CO₂ from recovery boiler stack emissions that are then transported and permanently stored in Class VI wells.

CO280’s method of removing CO₂ by retrofitting pulp and paper mills with a capture unit

CO280’s method of removing CO₂ by retrofitting pulp and paper mills with a capture unit

Pulp and paper mills are particularly well suited for carbon removal:

The cost is lower today than most pathways, and the approach has a path to costing less than $100/ton. This is for four reasons: (1) CO₂ is captured naturally via photosynthesis at no cost to CO280, (2) the CO₂ concentration in the flue gas from the recovery boiler is 350 times higher than that of atmospheric CO₂, making the capture process cheaper and more efficient relative to other pathways such as direct air capture, (3) CO280 takes advantage of existing infrastructure, significantly reducing capital and operating costs compared to building greenfield facilities, and (4) the majority of pulp and paper mills in the United States and Canada are located near CO₂ storage.

The potential for scale exceeds 500 million tons of CO₂ removal per year.¹ There are hundreds of pulp and paper facilities in the world today and approximately 77% of the CO₂ emissions are biogenic.

Retrofitting pulp and paper mills for biogenic CO₂ capture further proves the viability of CO₂ capture from other industrial facilities. The same type of capture unit that will be installed by CO280 could be used to reduce emissions in other industries, such as cement. The lessons learned from this project will reduce the cost and time required to install capture units at other facilities.

This approach takes advantage of a sustainable source of biomass. CO280’s projects take advantage of capturing the CO₂ stream from existing waste combustion systems (the recovery boilers). The biomass sourced for the pulp and paper mills comes from managed plantations with sustainable forestry certifications that are increasing the amount of carbon stored over time. This sourcing strategy meets the Frontier Biomass Sourcing Principles, which are used to evaluate prospective suppliers and throughout the lifespan of the contract to ensure every ton of carbon removal delivers the carbon impact intended.

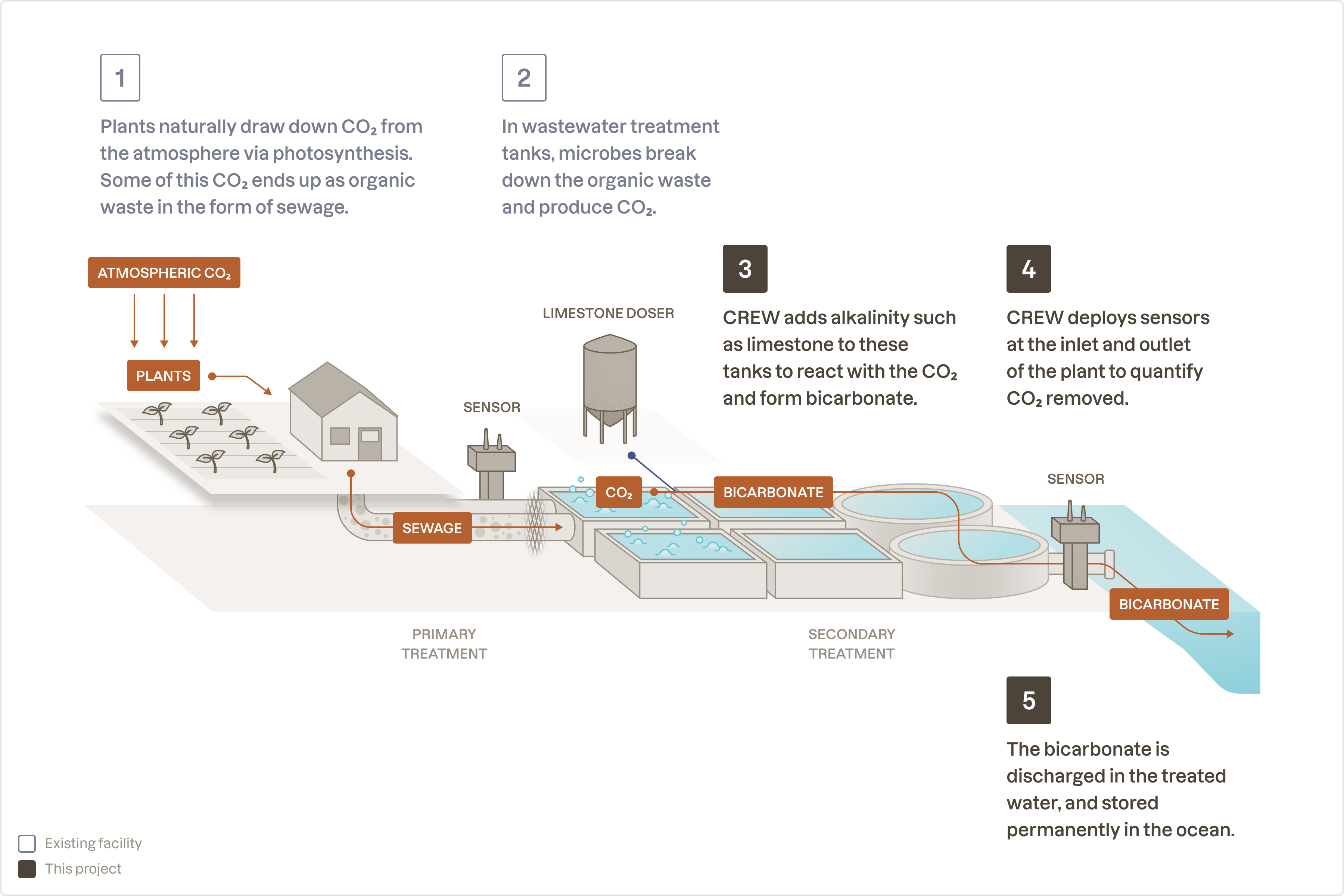

CREW works with wastewater treatment plants to integrate carbon removal into existing treatment processes. Typically these plants use microbes grown in treatment tanks, known as secondary treatment, to break down the organic waste entrained in the wastewater, which naturally produces biogenic CO₂. CREW’s approach involves the addition of alkaline minerals to those tanks, which react with the CO₂, capturing it as the more stable, aqueous bicarbonate ion. CREW’s monitoring system deployed at the inlet and outlet of the plant allows for robust quantification of CO₂ captured within the treatment process. The resulting dissolved bicarbonate is then safely discharged to oceans, rivers, or the subsurface where it is stored for thousands of years.

CREW’s method of removing CO₂ by adding fine-grained alkaline minerals, like limestone, to wastewater treatment plants

CREW’s method of removing CO₂ by adding fine-grained alkaline minerals, like limestone, to wastewater treatment plants

Wastewater treatment is particularly well suited for carbon removal:

This approach has a path to costing less than $100/ton. (1) CREW’s approach takes advantage of existing wastewater treatment infrastructure that naturally channels biogenic CO₂ into a closed system, reducing the amount of upfront capex and construction time required to get projects off the ground. (2) The CO₂ in wastewater treatment tanks is much more concentrated than CO₂ in the air (up to 10,000+ ppm vs. ~400ppm), minimizing the amount of energy needed to concentrate CO₂ and increasing the speed of the chemical reactions needed to permanently remove CO₂. And (3) the key ingredient, crushed limestone, is widely available and safe.

This approach is easily scaled and could reach over 500 million tons of CO₂ removal per year. (1) There are 100,000 wastewater treatment plants worldwide, and this approach requires little modification: the addition of a dosing system and CREW’s pioneering monitoring system. (2) This approach can be done nearly anywhere, as it does not require the buildout of CO₂ transport and storage infrastructure. Almost anywhere there is a population center with wastewater treatment, CREW enables the ability to remove CO₂.

The MRV certainty is higher than for other alkalinity-based approaches, as the mineral dissolution can be measured in-situ before the treated water is discharged. CO₂ is removed within the bounds of the plant and can be measured on short time scales. Relative to other weathering and marine carbon removal approaches, this improves buyer confidence and overall cost of delivering a ton of carbon removal.

Wastewater treatment is key to keeping our waterways safe, and can contribute to removing CO₂. Wastewater treatment practices are well established in order to remove pollutants and clean water. However, the treatment process can be complex, expensive, and sometimes require chemicals for controlling pH which could potentially be hazardous to worker health and carbon-intensive. CREW’s approach enables safe, optimized pH and alkalinity conditions for WWTPs, allowing them to achieve their mission of effectively treating wastewater while contributing to CO₂ removal.

Together, the pulp and paper and wastewater treatment sectors alone could potentially remove over 1 billion tons of CO₂ each year. These two approaches offer a model for how startups can partner with large industrial players to deliver carbon removal at scale. This model is already being used across industries: for example, integration with bioenergy facilities (like Exergi), with waste management systems (like Vaulted), and agricultural practices (like Lithos).

Frontier founders Stripe, Google, Shopify, McKinsey Sustainability, and members Autodesk, H&M Group, Workday, and Salesforce purchased as part of this round of offtakes. Aledade, Canva, Match Group, Samsara, SKIMS, Skyscanner, Wise, and Zendesk will also participate with purchases via Frontier’s partnership with Watershed.

Hannah Bebbington, Head of Deployment, Frontier: “Carbon removal isn’t just about developing entirely new technologies from the lab, but also building on existing industrial expertise and infrastructure. CO280 and CREW show how we can flip the switch on carbon removal in industrial processes, enabling big scale, fast.”

Jonathan Rhone, CEO, CO280: “Frontier’s extraordinary leadership and commitment to scaling up permanent, affordable carbon removals will enable CO280 to achieve network scale and impact. We are grateful to the entire Frontier team and Frontier members for their catalytic role in the carbon removal market and for their collaborative approach to partnering on these projects.”

Dr. Joachim Katchinoff, Co-Founder & CEO, CREW: “Securing this offtake with Frontier buyers enables CREW to accelerate the integration of carbon removal into existing wastewater infrastructure at a significantly faster pace and scale. This agreement not only allows us to expand our existing CO₂ removal projects but also benefits the wastewater sector by enabling safer and efficient wastewater treatment. Frontier’s support validates our mission to deliver measurable, permanent, and scientifically robust carbon removal today. This opportunity enables CREW to develop carbon removal in closed-system wastewater plants while informing how we do alkalinity-based carbon removal in open-systems across Earth’s water cycle.”

¹ Frontier literature analysis, including Tomberlin, et al.

² Frontier’s analysis of the wastewater industry today and projected growth.