- Vaulted will remove 152K of CO₂ between 2024 and 2027 on behalf of Frontier buyers. Of those, 18K tons are expected to be delivered in 2024.

- Vaulted’s approach offers 10K+ year permanence, near-term scalability, local co-benefits and has a line of sight to under $100 cost per ton.

Frontier has facilitated offtake agreements with Vaulted Deep, a carbon removal company that injects carbon-rich organic waste deep underground for permanent storage. Vaulted spun out of—and uses core tech from—Advantek Waste Management, a 10-year old industrial waste management company. Frontier buyers will pay $58.3 million to permanently remove 152,480 tons of CO₂ between 2024 and 2027, with options to purchase more tons from future projects at lower prices. Frontier buyers were Vaulted’s first customers in September 2023 through a small prepurchase of 1,666 tons—all of which have already been delivered and verified. This offtake agreement enables Vaulted to commission three new wells that are sited to optimize feedstock availability, transportation, and well capacity. As one of the first carbon removal spin-outs from a waste management company, Vaulted is an example of growing interest from large industrials to apply their expertise and assets to carbon removal.

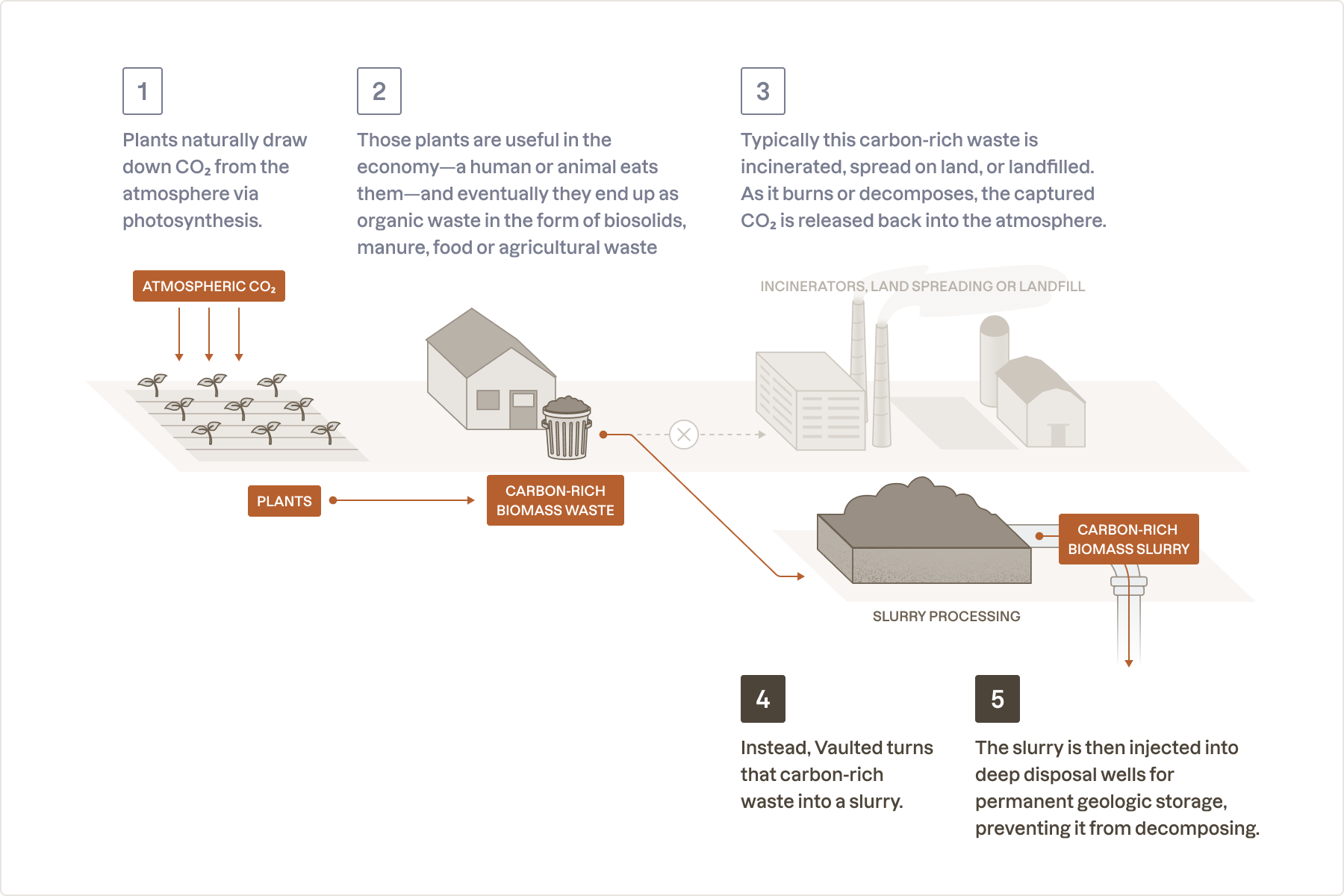

Vaulted’s approach starts with plants that naturally draw down CO₂ from the atmosphere via photosynthesis. Much of that ends up as carbon-rich waste in the form of biosolids, manure, food or agricultural waste that is incinerated, landfilled, or spread on land. As that waste burns or decomposes, the once-captured CO₂ is released back into the atmosphere. Vaulted prevents that re-release by turning the waste into a carbon-rich slurry and then injecting it into deep disposal wells for permanent geologic storage. The volume of carbon removed is measured by weighing the carbon in the biomass and subtracting emissions generated at every stage in the process, including transportation and energy usage.

Vaulted’s method of removing CO₂ via underground injection of waste biomass.

Vaulted’s method of removing CO₂ via underground injection of waste biomass.

Vaulted’s approach is compelling for a few reasons:

The potential for scale is large, thanks to an abundance of waste and flexible storage options. Waste biomass has the potential to deliver >300Mt of carbon removal annually in the US alone and a potential for 5Gt of capacity globally in theory¹. It can be injected underground using Class V injection wells or their equivalents, widely used to safely dispose of byproducts generated by industrial and agricultural activities. These wells can be built in a large variety of locations, making storage functionally unlimited for this approach.

The cost is relatively low today, and there’s a believable path to well under $100 per ton. This is due to 3 factors: 1) the CO₂ capture process happens naturally via photosynthesis at no cost, and wastes are aggregated by existing industrial infrastructure; 2) slurry injection technology can be done with minimal feedstock processing before injection, virtually eliminating processing costs; and 3) facility capex is inexpensive and uses commercially available equipment and construction services. A big driver of cost today is transportation—Vaulted transports biomass waste from waste partner sites, like landfills or waste water treatment facilities, to the injection wells. In the future, they will work with waste partners to co-locate injection wells directly on their sites, eliminating transportation costs.

The assets and expertise inherited from Advantek mean Vaulted’s poised to execute safely and quickly. As a spinoff from an established waste disposal company, Vaulted benefits from already-permitted well infrastructure as well as a team with longstanding operational experience and expertise in deep well waste injection technology. They’re set up to deliver CDR quickly and safely using mature, proven injection technology, and without a lengthy research and development period. Since launching late last year, Vaulted has already delivered several thousand tons, including 1,666 tons to Frontier buyers, as part of a small-volume prepurchase. As part of this offtake, Vaulted plans to deliver 18,321 tons to Frontier this year.

It offers health and environmental co-benefits deriving from safer waste disposal. Vaulted’s feedstock is sludgy waste like biosolids, manure, food and ag waste, and papermill sludge. These wastes are typically incinerated or spread on land for disposal, which can create a number of problems for nearby communities, including soil, water and air pollution, and foul odor. Diverting organic biomass waste to permanent sequestration has the potential to reduce environmental and human health harms in surrounding communities.

Frontier has facilitated purchases on behalf of Frontier Founding Members Stripe, Alphabet, Shopify, Meta, and McKinsey Sustainability, as well as Autodesk, H&M Group, JPMorgan Chase, and Workday. Also, Aledade, Canva, SKIMS, Skyscanner, Wise, and Zendesk have purchased via Watershed’s partnership with Frontier.

Biomass-based approaches to carbon removal are promising but require thoughtful biomass sourcing to have the intended climate impact. To help inform prospective customers of companies like Vaulted doing Biomass Carbon Removal and Storage, we’re sharing Frontier’s Biomass Sourcing Principles.

Julia Reichelstein, CEO at Vaulted Deep: “Vaulted's technology, developed by Advantek, has been primed to address carbon removal for decades—even before there was a market. Technologies like ours that can scale quickly without compromising durability or quality will lead the way. Our proven CDR is what makes possible Frontier’s largest offtake to date.”

Hannah Bebbington, Strategy Lead at Frontier: “Vaulted went from inception to delivering thousands of tons in just eight months and is now among the first carbon removal companies to sign a multi-million dollar offtake agreement. This shows what’s possible when the expertise of traditional industry players is repurposed for carbon removal.”

¹ Based on estimates in Snyder et al (2022)