CREW

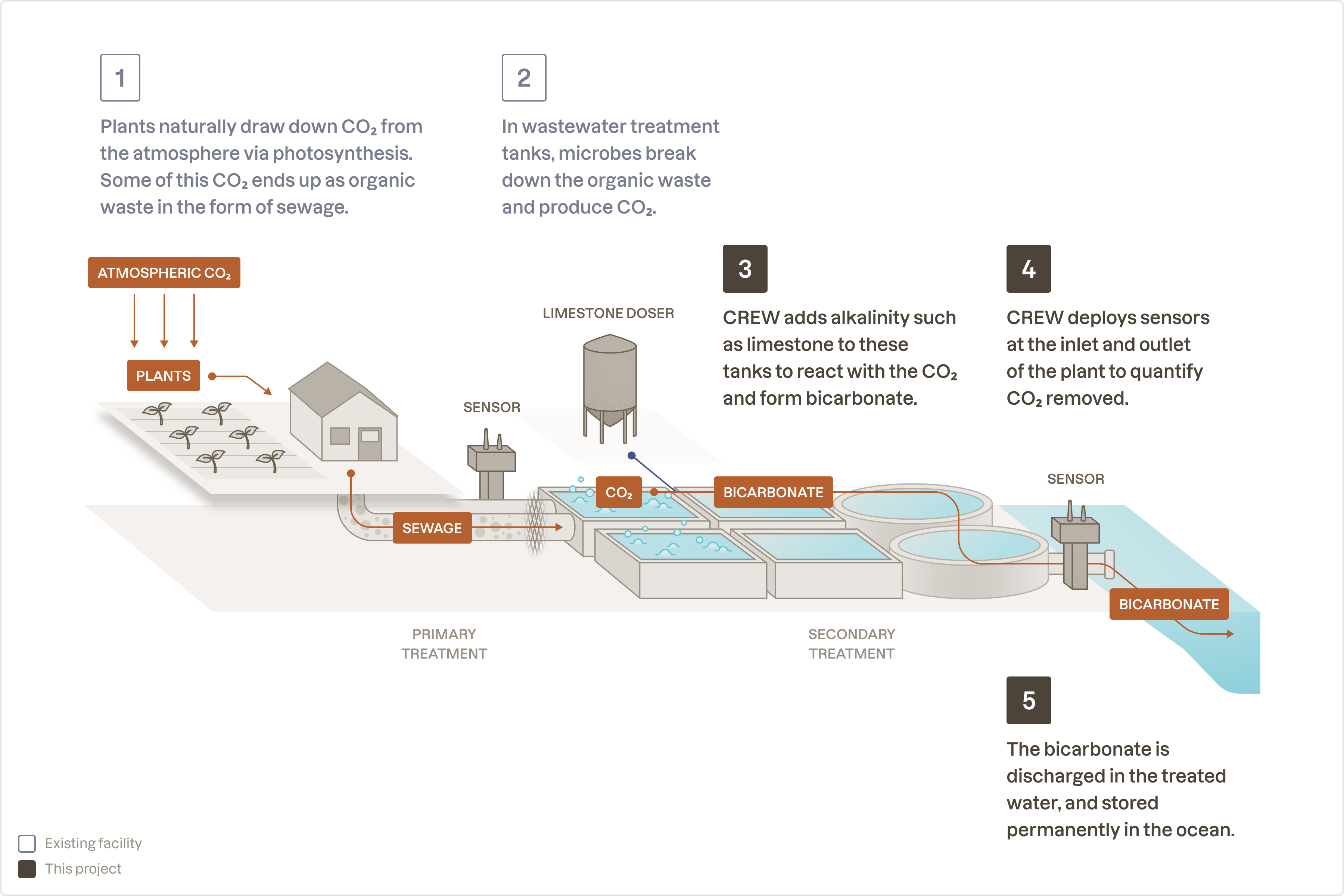

CREW adds alkaline minerals to wastewater treatment plants, converting CO₂ into bicarbonate which is then stored in the ocean.

- Pathway

- Marine carbon removal

- Contracted tons

- 71,877

- Track

- Offtake - 2024

- Total contract value

- $32.2M

- Location

- New Haven, CT, US

- Delivery timeline

- 2025 – 2030

The approach

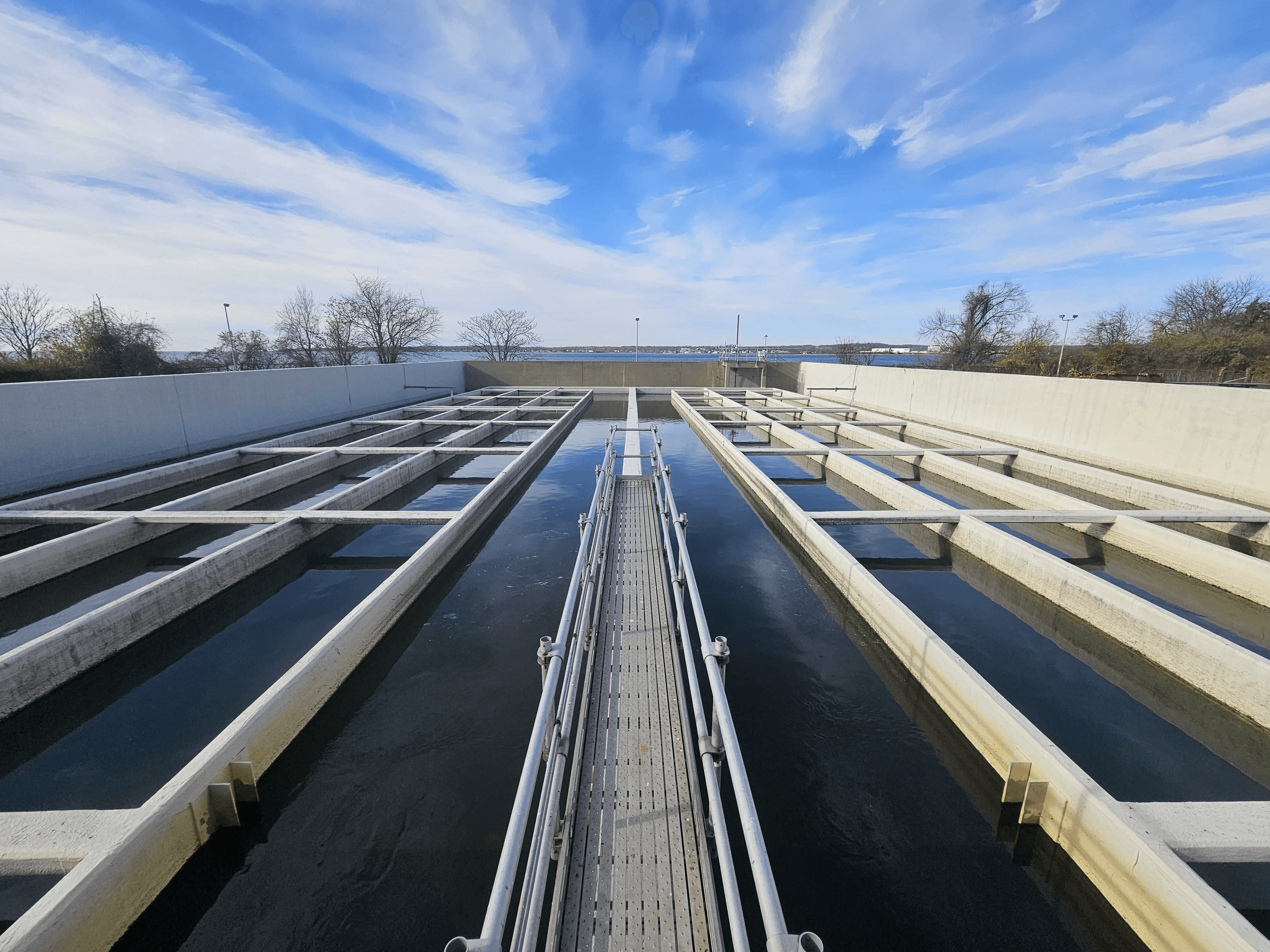

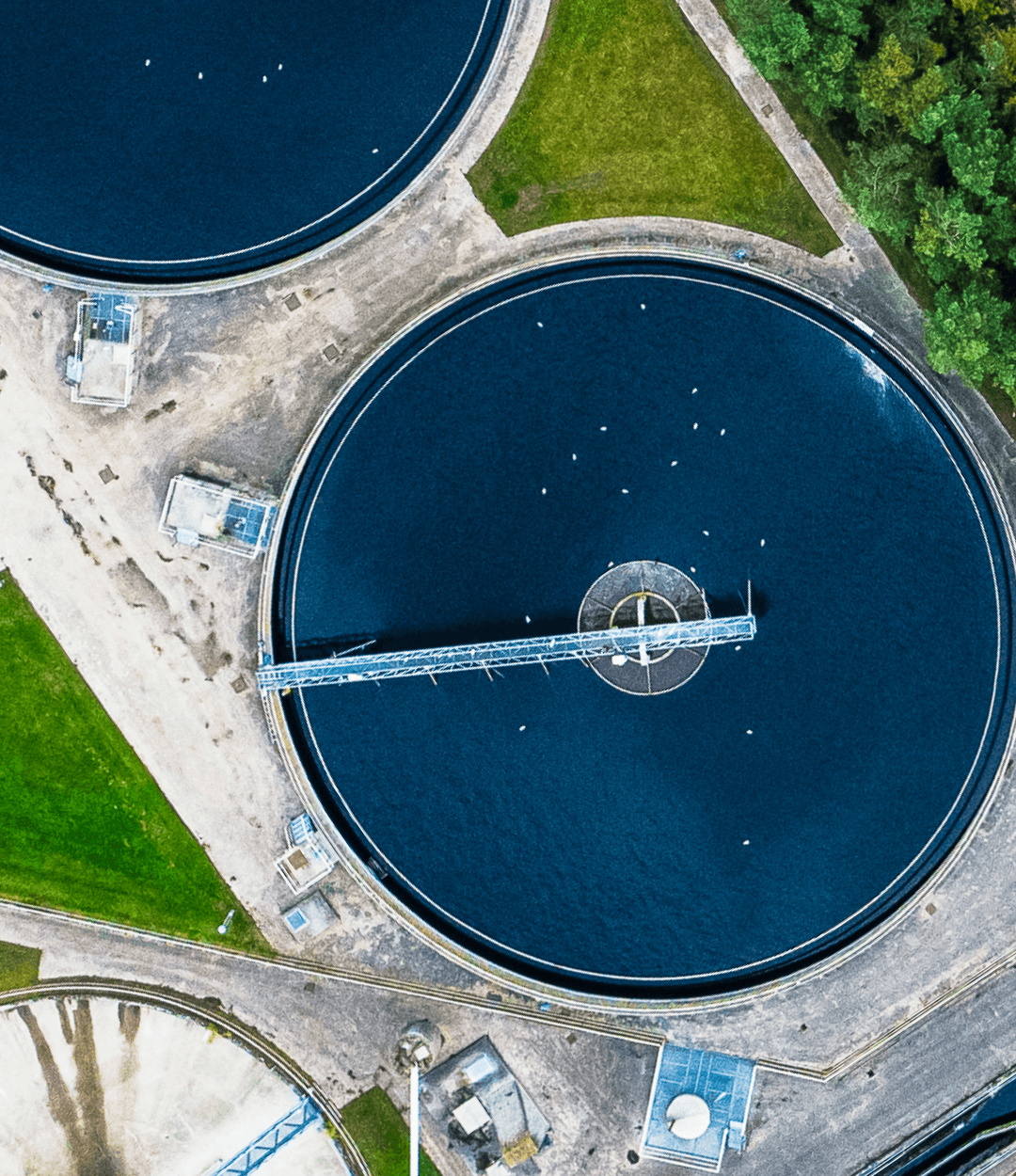

Wastewater treatment plants use microbes grown in treatment tanks, known as secondary treatment, to break down the organic waste entrained in the wastewater, which naturally produces biogenic CO₂. CREW’s approach involves the addition of alkaline minerals to those tanks, which react with the CO₂, capturing it as the more stable, aqueous bicarbonate ion.

CREW’s monitoring system deployed at the inlet and outlet of the plant allows for robust quantification of carbon dioxide captured within the treatment process. The resulting dissolved bicarbonate is then safely discharged to oceans, rivers, or the subsurface where it is stored for thousands of years.

The case for CREW

This approach has a path to costing less than $100/ton. (1) CREW’s approach takes advantage of existing wastewater treatment infrastructure that naturally channels biogenic CO₂ into a closed system, reducing the amount of upfront capex and construction time required to get projects off the ground. (2) The CO₂ in wastewater treatment tanks is much more concentrated than CO₂ in the air (up to 10,000+ ppm vs. ~400ppm), minimizing the amount of energy needed to concentrate CO₂ and increasing the speed of the chemical reactions needed to permanently remove CO₂. And (3) the key ingredient, crushed limestone, is widely available and safe.

This approach is easily scaled and could reach over 500 million tons of CO₂ removal per year. (1) There are 100,000 wastewater treatment plants worldwide, and this approach requires little modification: the addition of a dosing system and CREW’s pioneering monitoring system. (2) This approach can be done nearly anywhere, as it does not require the buildout of CO₂ transport and storage infrastructure. Almost anywhere there is a population center with wastewater treatment, CREW enables the ability to remove CO₂.

The MRV certainty is higher than for other alkalinity-based approaches, as the mineral dissolution can be measured in-situ before the treated water is discharged. CO₂ is removed within the bounds of the plant and can be measured on short time scales. Relative to other weathering and marine carbon removal approaches, this improves buyer confidence and overall cost of delivering a ton of carbon removal.

Wastewater treatment is key to keeping our waterways safe, and can contribute to removing CO₂. Wastewater treatment practices are well established in order to remove pollutants and clean water. However, the treatment process can be complex, expensive, and sometimes require chemicals for controlling pH which could potentially be hazardous to worker health and carbon-intensive. CREW’s approach enables safe, optimized pH and alkalinity conditions for WWTPs, allowing them to achieve their mission of effectively treating wastewater while contributing to CO₂ removal.

Pricing and delivery

The total offtake amount from Frontier buyers is $32.2M for 71,878 tons of CO₂ removed. The price accounts for both the removal itself as well as measuring, reporting and verifying (MRV) that each ton is safely and permanently stored.

¹ Frontier’s analysis of the wastewater industry today and projected growth.