CO280

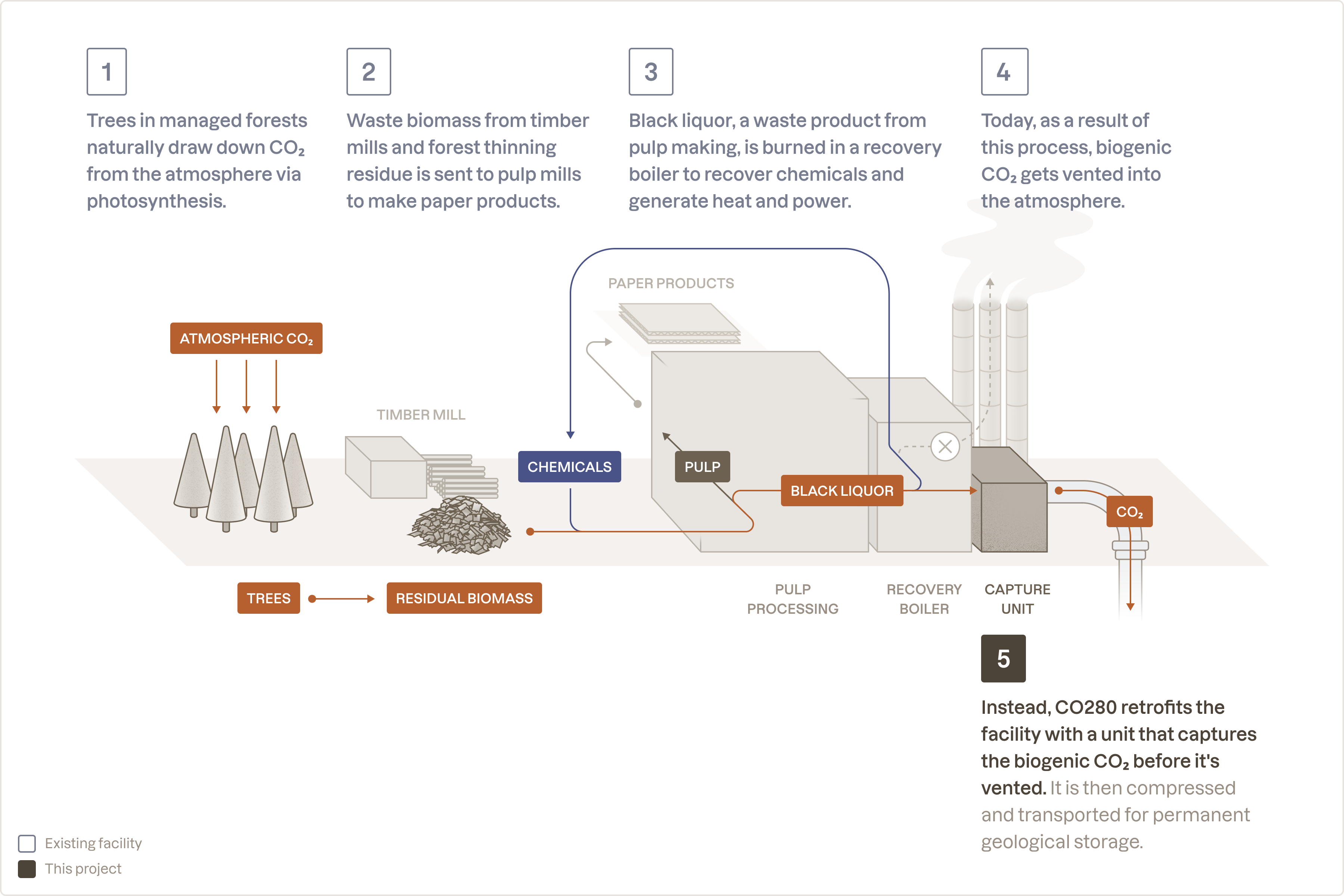

CO280 retrofits pulp and paper mills with capture units to extract the biogenic CO₂, which is then stored in geologic storage.

- Contracted tons

- 224,446

- Track

- Offtake - 2024

- Total contract value

- $48.0M

- Location

- Vancouver, British Columbia, CA

- Delivery timeline

- 2028 – 2030

The approach

CO280 partners with pulp and paper companies to remove CO₂ produced in the manufacturing of pulp, which is used to make containerboard, cardboard packaging, tissue, and other paper products. A pulp and paper mill first processes incoming biomass into a pulp, using steam, a mixture of chemicals, and pressure. The pulp is then used to make various products.

The leftover waste from the initial processing, known as black liquor, is fired in a recovery boiler to recycle chemicals back into the mill, and provide heat and power for the facility. CO280’s projects capture biogenic CO₂ from recovery boiler stack emissions, which is then transported and permanently stored in Class VI wells.

The case for CO280

The cost is lower today than most pathways, and the approach has a path to costing less than $100/ton. This is for four reasons: (1) CO₂ is captured naturally via photosynthesis at no cost to CO280, (2) the CO₂ concentration in the flue gas from the recovery boiler is 350 times higher than that of atmospheric CO₂, making the capture process cheaper and more efficient relative to other pathways such as direct air capture, (3) CO280 takes advantage of existing infrastructure, significantly reducing capital and operating costs compared to building greenfield facilities, and (4) the majority of pulp and paper mills in the United States and Canada are located near CO₂ storage.

The potential for scale exceeds 500 million tons of CO₂ removal per year.¹ There are hundreds of pulp and paper facilities in the world today and approximately 77% of the CO₂ emissions are biogenic.

Retrofitting pulp and paper mills for biogenic CO₂ capture further proves the viability of CO₂ capture from other industrial facilities. The same type of capture unit that will be installed by CO280 could be used to reduce emissions in other industries, such as cement. The lessons learned from this project will reduce the cost and time required to install capture units at other facilities.

This approach takes advantage of a sustainable source of biomass. CO280’s projects take advantage of capturing the CO₂ stream from existing waste combustion systems (the recovery boilers). The biomass sourced for the pulp and paper mills comes from managed plantations with sustainable forestry certifications that are increasing the amount of carbon stored over time. This sourcing strategy meets the Frontier Biomass Sourcing Principles, which are used to evaluate prospective suppliers and throughout the lifespan of the contract to ensure every ton of carbon removal delivers the carbon impact intended.

Pricing and delivery

The total offtake amount from Frontier buyers is $48.0M for 224,500 tons. The price accounts for both the removal itself as well as measuring, reporting and verifying (MRV) that each ton is safely and permanently stored.

¹ Frontier literature analysis, including Tomberlin, et al.