Arbor

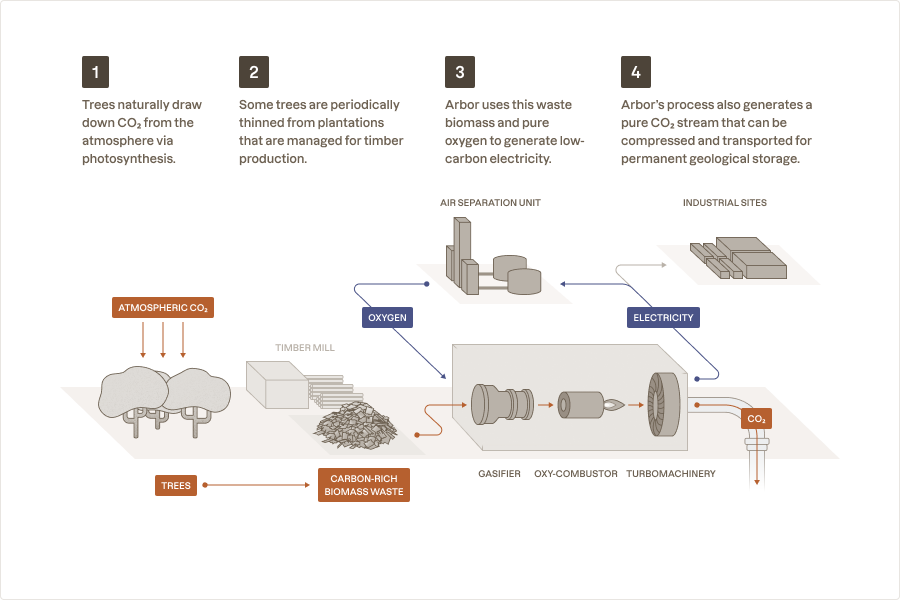

Arbor converts waste biomass into captured CO₂ and clean electricity.

- Contracted tons

- 120,002

- Track

- Offtake - 2025

- Total contract value

- $42.4M

- Location

- Los Angeles, CA, US

- Delivery timeline

- 2028 – 2030

The approach

Arbor removes CO₂ from the atmosphere by converting waste biomass into syngas which is then burned with pure oxygen in an oxycombustor, producing supercritical CO₂.

This supercritical CO₂ drives a turbine to generate clean electricity, and can be directly captured. For every ton of CO₂ that’s removed, Arbor’s system also supplies up to 1,000 kWh of clean electricity (the average household’s monthly electricity use).

The case for Arbor

Arbor’s system addresses the growing demand for clean baseload electricity. As hyperscalers build more datacenters, they need to balance their commitments to reduce emissions with the requirement for constant, dependable electricity. Arbor meets this double imperative by generating clean electricity and capturing CO₂, effectively reducing fossil fuel emissions while removing carbon from the atmosphere. Furthermore, Arbor’s system produces excess water as a byproduct of the biomass gasification and oxygen combustion process. In future projects, Arbor plans to sell this excess water for uses such as irrigation and data center cooling, minimizing the need for extra cooling water in their operations.

Arbor's technology can remove more CO₂ than BECCS approaches using conventional CO₂ capture technologies, such as amine solvents. Arbor’s process burns biomass with pure oxygen, producing supercritical CO₂ and water as the main byproducts. In contrast, other approaches often use regular air, resulting in exhaust that contains various gases. This complex mix makes capturing CO₂ more costly. In contrast, Arbor's exhaust consists mainly of water and CO₂, simplifying collection and storage and enabling capture rates exceeding 99%.

Arbor’s process could be the lowest cost approach to doing BECCS. Its compact design features an 18 MW turbine about the size of a car engine, allowing for efficient scaling and cost reductions. By integrating CO₂ capture directly with power generation, Arbor eliminates the added costs of separate capture units. This approach enables a ~10x increase in power and carbon removal for every 2-3x increase in size, potentially driving costs below $100 per ton of CO₂ removed.

Arbor’s project meets Frontier’s sustainable biomass sourcing principles. The company’s commercial facility will source biomass from thinnings of managed timber plantations, in areas where 1) the growth-to-drain ratio (the amount of biomass grown vs. harvested) is either stable or increasing, and 2) where pulp and paper mills that historically utilized these thinnings have shut down. Arbor is working with a credit issuer, Isometric, to quantify the emissions from their project so they can be deducted when calculating the net carbon removal.

Pricing and delivery

The total offtake amount from Frontier buyers is $41M for 116,000 tons. The price accounts for both the removal itself as well as measuring, reporting and verifying (MRV) that each ton is safely and permanently stored.