Frontier has awarded $2M in R&D grants to Leilac (UK) and SaltX (Sweden) to support the production of zero carbon lime — lime produced without net CO₂ emissions — on behalf of Stripe, Shopify, and Google. Zero carbon lime could be a low cost feedstock for several carbon removal applications. Frontier’s goal is to accelerate the lowest‑cost, most commercially ready processes for producing zero‑carbon lime, starting with these two companies.

Why zero carbon lime matters for carbon removal

Quicklime is made by heating limestone, one of the most abundant rocks on Earth. When quicklime later reacts with CO₂ from the atmosphere or ocean, it turns back into limestone, permanently storing the carbon in a solid rock. Because the reaction is natural and limestone is abundant, quicklime is very compelling for carbon removal, particularly for ocean liming and some approaches to direct air capture.

Reducing emissions in lime production

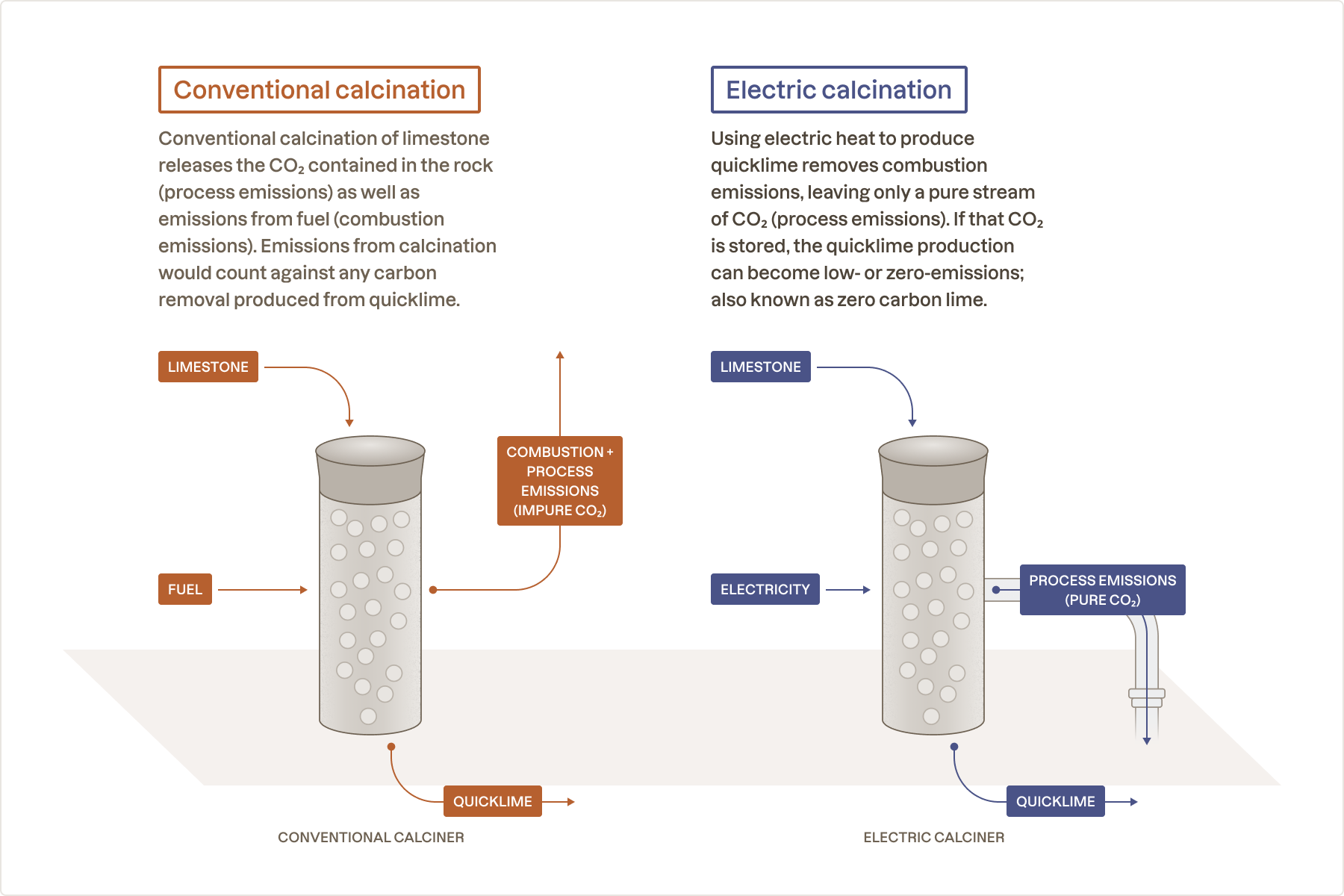

Today, making quicklime is carbon-intensive. Limestone is heated to very high temperatures in a calciner, which converts it into quicklime and releases CO₂ as a by-product. Conventional calciners vent that CO₂ as process emissions. If they run on fossil fuels, they generate additional emissions on top of that.

Those upstream emissions must be counted against any carbon removal project, and they can significantly erode its climate benefit. Producing quicklime without emissions is therefore a necessary piece of the puzzle to scale carbon removal pathways that rely on it.

One way to remove emissions from the process is by using electricity instead of fuel to produce heat. This eliminates energy emissions and leaves only the process emissions, which are easy to capture as they are just concentrated CO₂.

In the last decade, several electric calcination technologies have emerged to produce low- or zero-carbon lime for the cement industry, but high costs have limited their uptake. Quicklime intended for carbon removal does not need the same specifications as cement: the purity, particle size, moisture level, and other quality tolerances can be adjusted to reduce the cost of production. Designing electric calcination systems specifically for carbon removal applications could therefore lower the overall cost of quicklime-dependent approaches.

Conventional versus electric calcination.

Conventional versus electric calcination.

Meet the projects

Marine carbon removal | Salisbury, UK | R&D

Leilac’s calcination technology uses indirect heating to convert abundant carbonate rocks, such as limestone, into an alkaline product with low carbon emissions. The process is compatible with renewable energy sources, captures CO₂ released from the feedstock, and prevents contamination from combustion gases. The resulting alkaline material can be used for carbon removal (via ocean alkalinity enhancement or direct air capture) or to mitigate local ocean acidification.

Marine carbon removal | Stockholm, Sweden | R&D

SaltX builds electric arc calciners (EAC) which use plasma torches to heat limestone, converting it to high quality quick lime and releasing high purity CO₂ for storage. The plasma torch can generate heat at over 4,000℃ allowing a compact low-cost reactor. The quick lime is suitable for carbon removal uses like ocean alkalinity enhancement and mineral looping Direct Air Capture (DAC).