- NULIFE turns a waste disposal problem into a carbon removal solution.

- The company has already started delivering verified tons.

Frontier has facilitated an offtake agreement with NULIFE GreenTech, a Canadian company that converts biowaste into a concentrated bio‑oil and stores the CO₂ geologically in licensed salt caverns. With this deal, Frontier buyers will pay NULIFE USD $44.2 million to remove 122,000 tons of CO₂ between 2026 and 2030. Frontier buyers were NULIFE's first customers as part of a prepurchase in 2024 for which the company has already delivered more than half of the total volume contracted. This is Frontier's third offtake with a Canadian company, bringing Frontier's commitment in the country to over $100M.

Many agricultural and industrial sites produce biowaste that is awkward and expensive to manage—examples include oat hulls from milling, grease‑trap waste from food processors, sludge from canola crushing, biosolids from wastewater treatment, and so on. Left in piles or spread on fields, these materials decompose and release greenhouse gases, including CO₂ and sometimes methane.

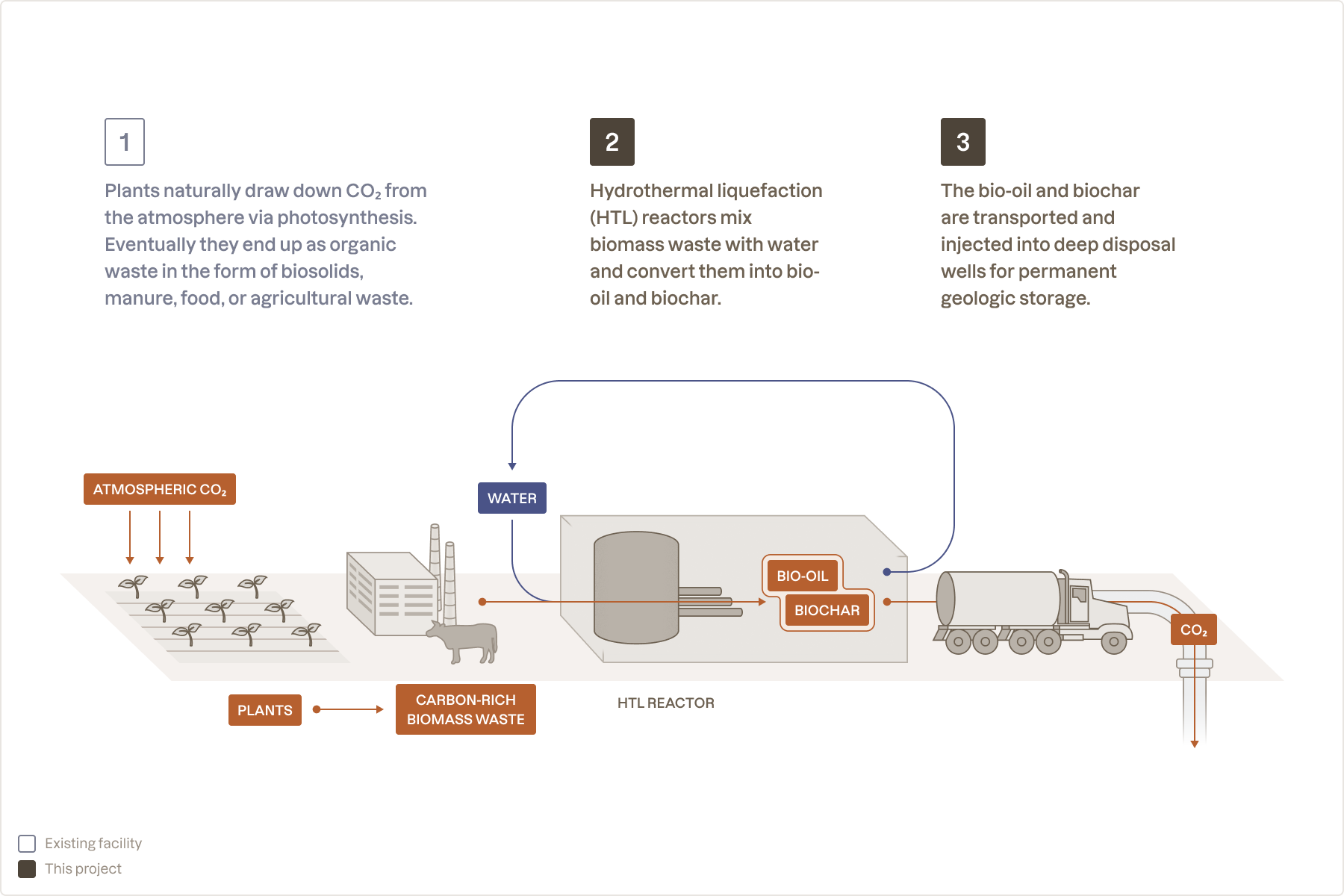

NULIFE addresses that problem with hydrothermal liquefaction (HTL), a process that converts biowaste into a transportable, storable product. An HTL reactor acts as a large industrial pressure cooker: NULIFE puts the biowaste into a sealed vessel and raises the temperature and pressure, which breaks the material down into new substances. Most of the carbon becomes a thick liquid called bio‑oil. The bio‑oil concentrates the carbon so trucks can carry far more carbon per trip than they could with raw wet waste, and NULIFE injects that liquid more than 1,000 meters underground into licensed salt caverns for long‑term storage. Carbon-rich solids (biochar) are also produced, which are injected together with the bio-oil. Injecting a mixture of solids and liquids increases the carbon removal efficiency of NULIFE's process, because more of the carbon in the biomass feedstock is permanently stored.

NULIFE's method of removing CO₂ via hydrothermal liquefaction and underground injection.

NULIFE's method of removing CO₂ via hydrothermal liquefaction and underground injection.

The case for NULIFE

NULIFE converts a local waste problem into a verifiable carbon removal pathway. Rather than stockpiling or spreading bio-residues like oat hulls, sludge, and grease—which would emit greenhouse gases as they decompose—NULIFE turns that material into bio‑oil and stores it in licensed underground caverns. In doing so, the company gives plant managers a disposal option and creates a steady supply of material for measured removals.

The approach is already delivering verified tons. NULIFE's Ontario Avenue site, in Saskatoon, Canada, has logged thousands of operating hours on commercial HTL processors and has delivered tons independently verified by Isometric. Those deliveries and the ongoing operations reduce the technical and measurement uncertainty that often surround early-stage projects.

Concentrating waste into bio‑oil makes transport and storage practical. Raw biowaste (especially wet waste) is low in carbon density and costly to move. By turning it into a carbon-rich liquid, each truck can carry far more carbon per trip, enabling aggregation from many sites and centralized injection into permitted caverns rather than requiring an injection well near a waste source.

HTL could deliver at gigaton-scale. NULIFE's process works on a wide range of biomass waste types, including dry biomass, such as woody biomass and crop residues, as well as wet waste like manure and sewage sludge. Given this flexibility, Frontier estimates HTL could reach 1.5 gigatons of CO₂ removal per year by 2040.

Frontier has facilitated purchases on behalf of its Founding Members Stripe, Google, Shopify, and McKinsey Sustainability, as well as members Autodesk, H&M Group, and Workday. Additionally, Aledade, Canva, Match Group, Samsara, SKIMS, Skyscanner, Wise, and Zendesk have participated via Watershed's partnership with Frontier.

Jerry Kristian, Co‑founder, NULIFE: "Frontier's decision to proceed with this offtake is a strong validation of the engineering rigor, transparency, and real-world waste-management value behind our BiCRS platform. Our modular HTL units enable rapid, repeatable deployment, supporting scalable growth across Canada and internationally."

Hannah Bebbington Valori, Head of Deployment, Frontier: "NULIFE turns an everyday waste problem into measurable, long‑term carbon removal. This is a good example of how smart waste disposal can double-up as a carbon removal solution that could deliver at gigaton scale."