- Frontier buyers will pay 280 Earth $40 million to remove 61,571 tons of CO₂ between 2024 and 2030.

- 280 Earth’s approach uses a proprietary ‘continuous capture’ process built largely with commercially available components.

- The flexible process can be powered by waste heat from data centers, or clean electricity.

Frontier has facilitated another set of direct air capture offtake agreements, now with 280 Earth, a company employing a novel DAC system that permanently removes carbon dioxide from the air. Frontier buyers will pay 280 Earth $40 million to permanently remove 61,571 tons of CO₂ between 2024 and 2030 at their pilot facility in The Dalles, Oregon. The pilot module at The Dalles facility was completed in May 2024, and the Frontier buyers are the first to purchase from that unit. The offtake agreements will help 280 Earth build and operate additional modules at the facility.

Direct air capture remains a promising removal pathway. First, it can scale to multiple billions of tons of removal per year without the feedstock limitations that constrain biomass carbon removal and storage (BiCRS) and enhanced weathering approaches. Second, measuring and verifying carbon removed is simpler than most other pathways, for example enhanced weathering or ocean CDR. However, the energy demands and costs of constructing and operating complex DAC facilities make it more expensive per ton of CO₂ removed today.

280 Earth solves for these challenges with a flexible system design that’s built with commercially available components and can draw power from several sources, including electricity or industrial waste heat. When integrated with data centers, which generate significant amounts of heat and require substantial cooling, 280 Earth’s approach can use water vapor captured during the removal process to provide the additional benefit of reliable cooling capacity, reducing water usage. 280 Earth estimates that a 60 megawatt data center co-located with a 50 kiloton per year DAC system could save the center at least 200,000 tons of water annually. As the growth of artificial intelligence increases the demand for data processing, the need for data cooling is forecasted to grow exponentially,¹ further expanding the scenarios where DAC systems could be integrated into data centers.

The case for 280 Earth

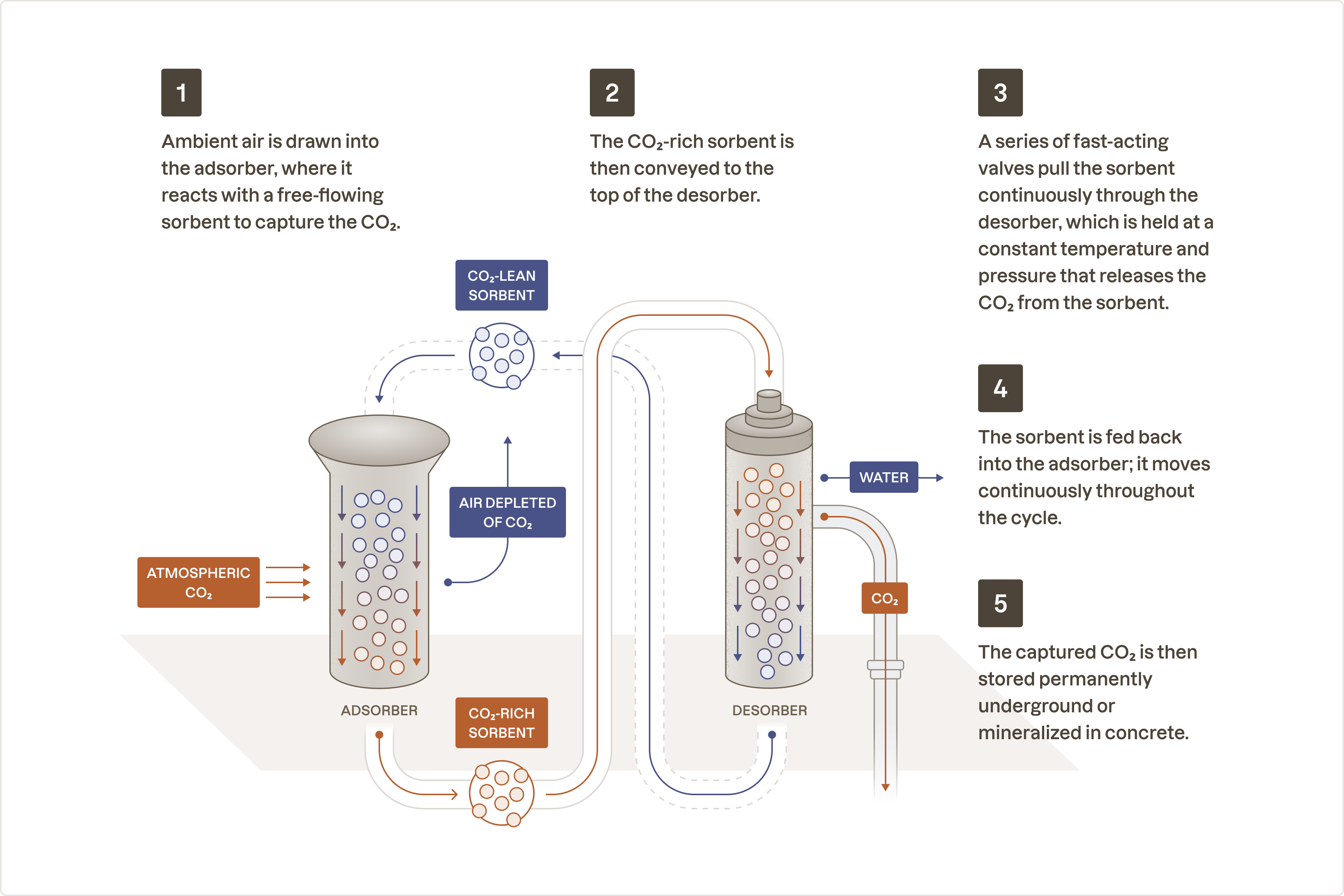

280 Earth was originally launched in 2018 at X, the moonshot factory founded by Google, and spun out in 2022. They are working toward driving down the cost curve for DAC with an approach that minimizes both capital and operating costs. Their system works continuously by pulling air into contact with a proprietary sorbent developed by the 280 Earth team that captures the CO₂. The CO₂-rich sorbent is conveyed to a vacuum chamber that is kept at a constant temperature and pressure, where it releases the CO₂. The pure stream of CO₂ can then be permanently stored underground or mineralized in concrete.

280 Earth’s method of continuously removing CO₂ from the atmosphere.

280 Earth’s method of continuously removing CO₂ from the atmosphere.

This approach is distinct for several reasons:

The system uses less energy by employing a continuous process and separate chambers for adsorption and desorption. Many DAC technologies rely on a batch process for adjusting the temperature and pressure of a single chamber for binding and separating CO₂ from the sorbent. 280 Earth instead moves the sorbent continuously between two separate, gravity-fed chambers. This “move the car, not the factory” approach reduces the energy loss associated with reheating, cooling, and changing the pressure of a single chamber.

It can be powered by heat from several sources, including industrial waste heat. Data centers and other industrial operations generate large amounts of waste heat that cannot be easily repurposed. 280 Earth’s facility can be situated to use the waste heat and provide cooling services. The system can alternatively operate effectively on 100% electricity.

The system is faster and less expensive to build because it is modular. Commercially-available components can be purchased in bulk, customized where needed, and skid-mounted for straightforward transportation and integration. This design avoids the costs and delays associated with commissioning proprietary parts and assembling them on site.

280 Earth has a strong team and partnerships. The 280 Earth technology was developed for over five years internally at X, the moonshot factory, which enabled them to create a sorbent that is high performing and physically stable, as well as design an energy-efficient process from the ground up. From the outset, 280 Earth has collaborated closely with equipment manufacturers as well as engineering and construction partners to design and test components and processes. These partnerships have helped expand its team’s team capacity and build a foundation for scale.

Frontier has facilitated purchases on behalf of Frontier Founding Members Stripe, Alphabet, Shopify, Meta, and McKinsey Sustainability, as well as Autodesk, H&M Group, JPMorgan Chase, and Workday. Also, Aledade, Canva, Samsara, SKIMS, Skyscanner, Wise, and Zendesk have purchased via Watershed’s partnership with Frontier.

John Pimentel, Chief Executive Officer 280 Earth: “Frontier’s forward-thinking members are providing critical leadership to attract private sector investment to decarbonize our atmosphere. This contract provides revenues that help 280 Earth drive down costs for our highly efficient direct air capture system."

Hannah Bebbington, Head of Strategy, Frontier: "DAC’s benefits make it an important potential part of the global carbon removal portfolio, but we need smart ways to lower costs and scale the pathway. 280 Earth’s unique process design offers them a pathway to overcome the challenging cost barrier for DAC."

¹ At current innovation speed, the computing power required for AI is doubling every 100 days and is projected to increase by more than a million times over the next 5 years, Zhu at al 2023.