Phlair

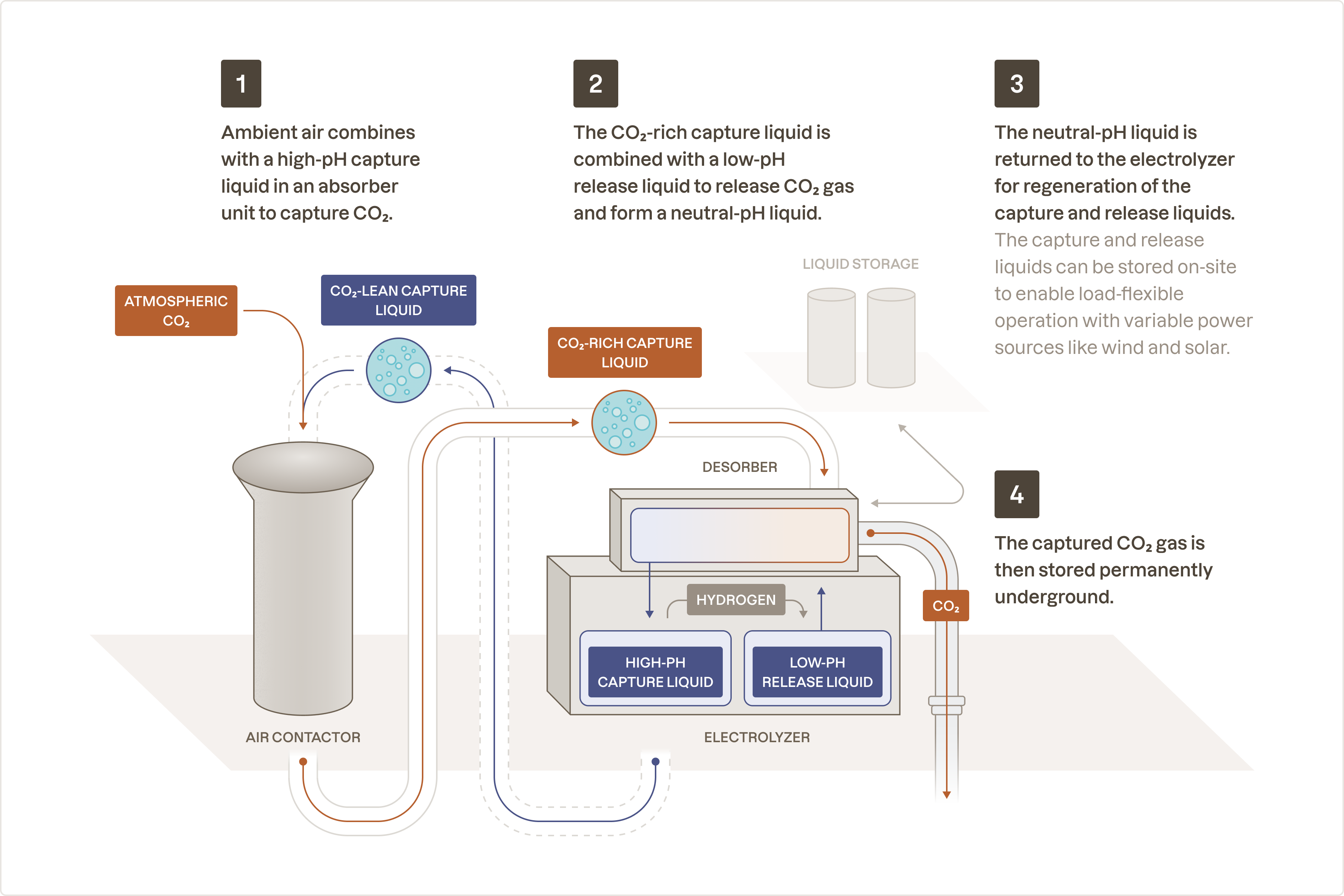

Phlair uses an electrochemical pH-swing process to remove CO₂ from the air

- Pathway

- Direct air capture

- Contracted tons

- 47,001

- Track

- Offtake - 2025

- Total contract value

- $30.6M

- Location

- Munich, Germany

- Delivery timeline

- 2027 – 2030

The approach

Phlair’s closed loop system works by contacting air with a high-pH liquid to capture CO₂. Once the capture liquid becomes saturated with CO₂, it is mixed with a low-pH release liquid to neutralize the solution and liberate the captured CO₂ as a concentrated gas, which is injected underground for durable storage. The remaining CO₂-depleted, neutralized liquid is fed into a hydrogen-looping electrolyzer for regeneration of the high-pH capture liquid and low-pH release liquid. This process continuously cycles, enabling ongoing CO₂ capture.

When there is plenty of sunlight and solar power is cheapest, Phlair can overproduce the capture and release liquids for storage in tanks. When the sun sets or when electricity prices are high, Phlair can shut down the energy-intensive electrolyzer and continue operating the CO₂ capture and release steps, drawing from the liquid stored in the holding tanks. This design allows the liquid holding tanks to effectively serve as substitutes for batteries, enabling continuous operation while minimizing energy cost.

The case for Phlair

Phlair’s approach has the potential to enable low-energy DAC. Phlair is developing an all-electric design system that’s energy-efficient relative to other DAC approaches, targeting less than 1.5 MWh of energy per ton of CO₂ removed. Their electrolyzer can run on variable electricity inputs while the produced liquids for capture and release can be stored at low additional cost. This concept makes Phlair uniquely compatible with low-cost, intermittent renewable energy sources.

Phlair has a credible path to low cost. First, the low energy requirement and load flexible operations of their hydrogen-looping, all-electric direct air capture system allows Phlair to manage electricity costs by operating at maximum capacity when solar energy is plentiful and reduce output when energy costs rise. Second, the system is modular and requires low customization, which minimizes capital costs and facilitates rapid iteration, production and installation of equipment. Core components of Phlair’s electrolyzer stack will benefit from application and learning in other industries, such as hydrogen production and fuel cell power systems, which further accelerates learning rates.

Despite being a young company, Phlair has demonstrated they can move fast and with rigor. In just two years, Phlair has gone from a lab-scale system to an outdoor pilot, hired a stellar team, and secured CO₂ storage and energy partners crucial to their growth.

Pricing and delivery

Frontier buyers’ total offtake is $30.6 million for 47,000 tons to be delivered between 2027 and 2030 at Phlair’s first commercial facility—Project Dawn—in Alberta, Canada. The price accounts for both the removal itself as well as measuring, reporting, and verifying (MRV) that each ton is safely and permanently stored. This agreement includes key milestones that must be met prior to delivery, including sharing a community benefits plan, demonstrating clean electricity sourcing, securing permits for storage, and scale-up technical specifications.