Heirloom

Heirloom uses limestone to remove CO₂ from the air.

- Pathway

- Direct air capture

- Contracted tons

- 26,889

- Track

- Offtake - 2023

- Total contract value

- $26.6M

- Location

- Brisbane, CA, US

- Delivery timeline

- 2025 – 2030

The approach

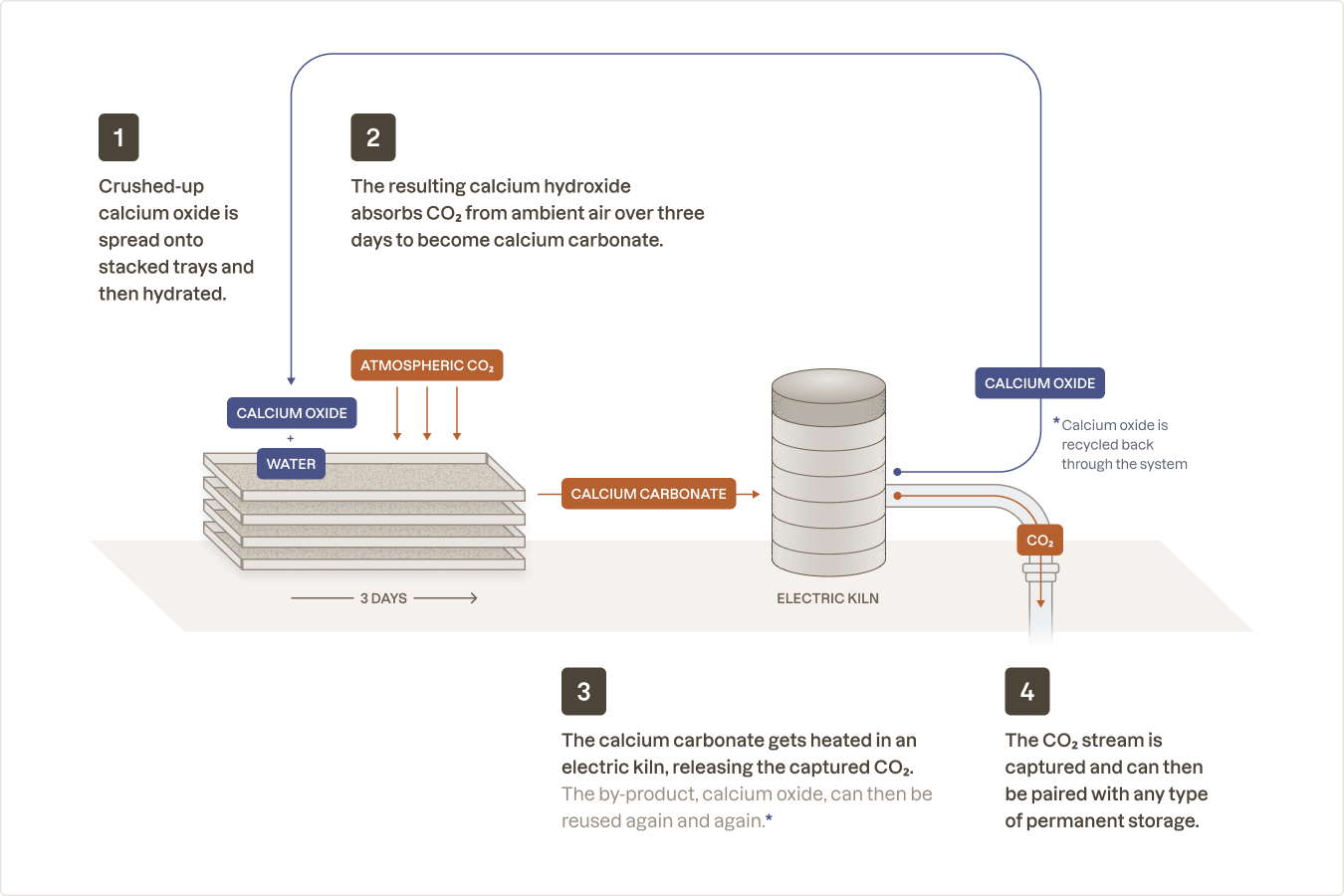

In Heirloom’s process, crushed limestone is heated to remove the CO₂ stored in the rock and then spread on stacked trays and hydrated to expose the now highly reactive rock to the ambient air. Over the course of three days (as opposed to the months to years it would take in nature) the minerals absorb CO₂.

They’re then moved into an electric kiln and heated for a few seconds, resulting in a stream of CO₂ that can be paired with any type of permanent storage. The same crushed rock is then redistributed back onto the trays, and the cycle begins again.

The case for Heirloom

DAC offers a promising path to permanent CDR that, in principle, meets the majority of Frontier’s target criteria—it’s highly durable, relatively easy to measure and verify, and takes up a relatively small physical footprint. The overarching drawback for DAC is the high cost of the capture, which is largely driven by the significant energy required to power the process as well as the upfront capex. In the medium-term, risk for DAC is the availability of low-cost 24/7 clean electricity, which is also needed to decarbonize the grid.

Heirloom’s core innovation is the use of limestone (an inexpensive, abundant, and effective material that absorbs CO₂ naturally) coupled with a modular and repeatable process. Unlike many other DAC companies, their sorbent has already achieved its target performance. Instead, they’re taking on engineering and operational risk to efficiently process hundreds of thousands of trays of ground limestone.

Heirloom is taking a unique approach to DAC that diversifies the field’s DAC bets. DAC companies are exploring a wide range of strategies to reduce cost and get to scale, including active vs. passive contacting, solid vs. liquid capture, materials, and so on. Heirloom is betting that an inexpensive and naturally occurring material, a modular and repeatable process, and an electric kiln powered by renewable energy (to eliminate fossil fuel consumption) will yield a superior solution.

Heirloom’s path to achieve low-cost removal relies largely on capex and opex declines (vs sorbent breakthroughs) that come from the simplicity of the process, huge economies of scale and operational excellence. Reducing capex, which is Heirloom’s immediate priority, relies on economies of scale gains from mass manufacturing, extending plant lifetimes, and reducing their cost of capital. Opex declines rely on reducing labor and maintenance, as well as energy opex (from both increased efficiency and reduced energy prices). Much of this work has been demonstrated before in other industries, including the solar and wind industries. Heirloom does not need to reinvent the wheel in many instances, but rather adopt and scale best practices from existing industrial facilities.

Still, Heirloom’s scaleup is not guaranteed. Their greatest risk is the combination of costs remaining stubbornly high for too long, making it challenging for them to raise enough customer demand to continue scaling. Heirloom has the direct support of 45Q through 2032, as well as up to $600M in government financing through the DOE’s DAC Hub program. Still, given their high starting costs, this is a risk, but not one that is entirely unique to Heirloom.

Pricing and delivery

Frontier buyers’ total offtake is $26.6M for 26,900 tons. The price accounts for both the removal itself as well as measuring, reporting and verifying (MRV) that each ton is safely and permanently stored. This agreement includes key milestones that must be met prior to delivery, including sharing a community benefits plan, presenting results from their FEED study, signing a PPA for renewable energy on their local grid, and securing permits for storage.